Advance Manufacturing Technology Labs

The manufacturing industry is constantly evolving with the advancement of technology, where new processes, tools and equipment allow manufacturing companies to produce products more efficiently.

Advanced manufacturing leverages the innovation in technology to manufacture better and improved products and/or improve the manufacturing processes. By integrating technological processes into manufacturing, companies are becoming more efficient in their production processes by increasing output, reducing waste, conserving energy better, reducing emissions and thereby increasing their profitability.

While more industries pursue Advanced Manufacturing, they are seeking new talent that can help them achieve their goals. Therefore, this field is very attractive for students who are interested in manufacturing systems and like to develop a career in advanced manufacturing systems.

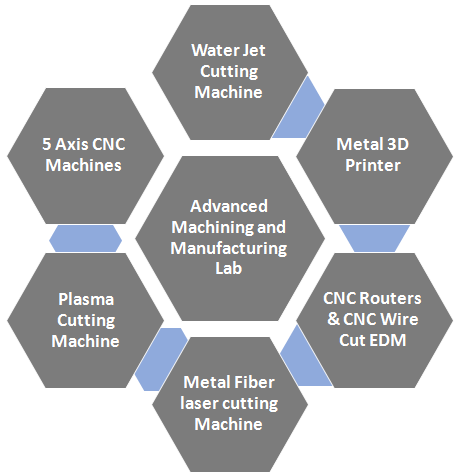

EDNEX SOLUTIONS FOR ADVANCED MANUFACTURING:

EdNex helps universities and industries to implement training solutions that can help develop a skilled workforce to achieve their advanced manufacturing goals.Students will learn from a range of topics that include :

Water Jet Cutting Machine

Desktop waterjet cutting machine cut any materials by combining high-pressure waterjet technology with several electro-mechanical systems to bring you an all-in-one cutting solution. These compact waterjet machines allow you to make things with professional-grade quality and are a must-have for every workshop. Some of the material that the waterjet can cut through are Aluminum, Copper, Stainless Steel, Steel,Titanium, Plastics and Rubber,Ceramics, stone and Carbon Fibre.

Plasma Cutting Machine

The Plasma mechanized systems are used to cut a wide range of conductive materials, including mild steel, carbon steel, stainless steel, aluminum, copper, brass, and other metals.Plasma Cutter systems include a range of plasma cutting tables for education that are engineered to deliver optimal repeatability and performance for your classroom or FabLab. With several sizes to choose from, the Plasma Cutter Pro machines fit easily into any classroom and require no assembly, arriving at your facility ready to use.

The plasma cutting systems also come with:

Hypertherm CNC Plasma Torch Systems: Portable, professional-grade air plasma cutting systems for cutting and gouging of any electrically conductive metal.

Mach3: A CNC plasmasystem that helps control the motion of the router by processing G-Code into physical movements. While offering many advanced features found in more complex control systems.

VCarve Pro: The best and easiest to use CAD/CAM software for CNC routers, VCarve Pro is used to create the files used by the router to bring projects to life. This software works with 3D / 2D files created by your favorite CAD software and popular graphics files like JPEG and SVG for those more artistically inclined.

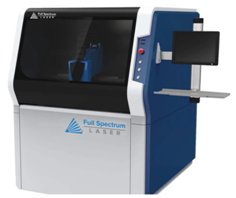

Metal Fiber laser cutting Machine

Perfect for space constrained applications, the Fiber Laser Metal Cutting Machine operates at the same laser power and capabilities as the flatbed 500w fiber laser but in a footprint that will fit through a regular doorway. Rapidly cut many metals with a kerf less than 25um (0.001″): alloy/carbon/stainless steel, copper, aluminum, gold, silver, titanium. Applications include sheet metal enclosures, car bodies, jewelry and more.

Metal 3D Printer

This high-caliber 3D metal printer deploys a laser-based powder-bed fusion technology in which a fiber laser selectively melts thin layers of metal powder, one at a time, to create parts directly from a 3D-CAD model. Metal powder-bed fusion provides high-quality and complex parts. It reduces total cycle time by about 50% and removes the need for wash/debinder and sintering/oven equipment used in bound metal deposition, atomic deposition additive manufacturing or other FDM-like metal 3D printers.

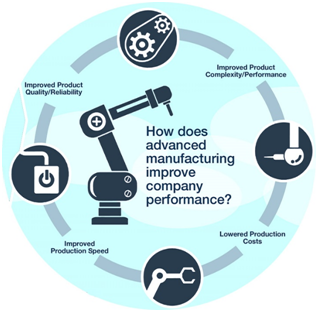

Industries are looking for people with specialized skills who can:

- Implement and control automated manufacturing processes

- Design components and assemblies

- Use 3D printers, laser cutters, and CNC equipment to fabricate prototypes

- Illustrate flow of materials and resources within the manufacturing cycle

- Control a manufacturing system to create finished product

- Program material handling robots and equipment

- Perform system analysis and master the troubleshooting process

- Master lean manufacturing process to maximize production of a product

Have theoretical knowledge and hands-on practice in electronics, mechanics, computer systems and software control systems.